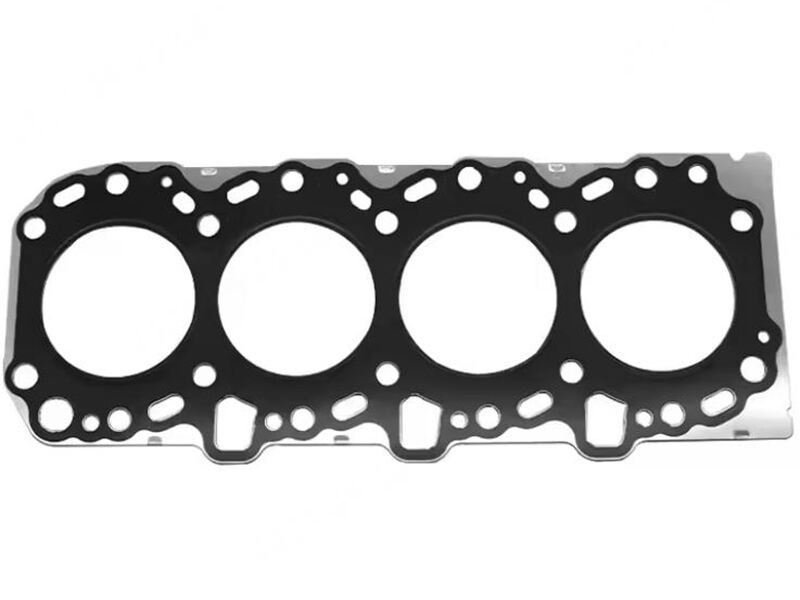

The cylinder head gasket, known as the "heart seal" of the engine, is an inconspicuous component tasked with the critical job of sealing the high-temperature, high-pressure combustion chamber, coolant passages, and oil galleries. Its performance directly impacts the engine's power, efficiency, reliability, and lifespan. Looking at the global automotive industry, the American, Japanese, and Korean sectors represent three major vehicle types, each with distinct design philosophies, market positions, and manufacturing principles. These differences are profoundly reflected in the performance and design of their cylinder head gaskets.

I. Root Causes: Design Philosophy and Performance Orientation

To understand the differences in component performance, one must first understand the underlying design(philosophies/concepts):

American Brands: Traditionally focused on "muscle," large displacement, and high torque. Engines tend to deliver powerful thrust at medium RPMs, placing extremely high demands on components' ability to withstand high temperatures and high-pressure shocks. The design has often been more "robust and sturdy" to cope with extreme operating conditions.

Japanese Brands: The core philosophy is "lean production" and "reliability above all." They pursue ultimate fuel economy, smoothness, and trouble-free mileage. Designs are precise, advocating for the "just right" amount of redundancy, with meticulous attention to material science and manufacturing processes.

Korean Brands: As a later challenger, their(philosophy) is "high cost-performance" and "rapid iteration." Building upon absorbed Japanese and American technology, they focus more on cost control to attract consumers with more features and longer warranties. Their component performance is balanced, aimed at meeting the daily needs of the vast majority of users.

II. Specific Differences in Cylinder Gasket Performance

Based on the above(philosophies), the cylinder gaskets of these three vehicle types exhibit different characteristics in material selection, structural design, and performance emphasis.

1. Materials and Manufacturing Process:

American: Historically widely used asbestos-faced metal gaskets to withstand the rough treatment of large-displacement engines like V8s. Modern American turbocharged engines (e.g., EcoBoost series) commonly use Multi-Layer Steel (MLS) head gaskets. This type of gasket consists of three or more layers of thin steel sheets laminated together, with special anti-stick coatings and sealing beads. It offers extremely high resistance to knock and thermal load performance, perfectly meeting the challenges of high temperatures and pressures brought by turbocharging. The manufacturing process is complex and costly.

Japanese: They are masters of composite materials and MLS technology. Japanese manufacturers (e.g., Toyota, Honda) invest heavily in material science, developing various elastic gaskets made from composites of graphite, rubber, and metal, which offer good sealing and are environmentally friendly. For high-performance models (e.g., Subaru WRX, Nissan GT-R) or turbocharged engines, they equally employ top-tier MLS technology. The characteristics of Japanese MLS gaskets lie in their extremely high manufacturing precision and exquisite surface treatment processes, pursuing a perfect fit with the block and head to achieve long-term stable sealing.

Korean: They closely follow technological trends, widely adopting mature composite materials or cost-effective MLS solutions in mainstream models. Their material and process selection heavily emphasizes cost-effectiveness. While ensuring design standards and warranty period requirements are met, priority is given to market-proven, high-value solutions. Performance is reliable, but the safety margin under extreme operating conditions might not match that of top-tier American and Japanese products.

2. Performance Emphasis:

American: Ultimate Reinforcement, Resisting Shock. The performance focus is on resisting high temperatures, high pressure, and anti-knock. Everything is geared towards stabilizing the immense cylinder pressure from turbocharging and supercharging, preventing "blown head gaskets."

Japanese: Long-lasting Seal, Stable Reliability. The performance focus is on long-term sealing stability, corrosion resistance, and anti-creep capability. Ensuring coolant and oil never mix throughout the engine's entire lifecycle, maintaining thermal management efficiency, and safeguarding fuel economy.

Korean: Balanced Durability, Meeting Standards. The performance focus is on meeting design targets, ensuring sufficient strength and durability to support their lengthy warranty policies (e.g., 100,000 km / 10-year warranty), while strictly controlling costs.